The Rise and Fall of Yorkshire Tails

written by Karl Grave in 2002.

This fascinating article is reproduced from the website of the Whiting Society, with their kind permission. The Whiting Society own the copyright, and it should not be reproduced without their permission. Visit www.whitingsociety.org.uk/index.html to read more interesting articles and to see their extensive range of books etc.

A Yorkshire Tail is a length of tufting at the very bottom of the bell rope instead of the doubled back type seen in most towers. As far as we know, from a once wide distribution, by 2002 Yorkshire tail ends were present in only about a dozen towers.

![]()

Yorkshire Tails seem to have been a Victorian invention. In the North, six bells were normally rung 'Cartwheel' that is, without the open lead. This rhythm doesn't require the rope to be cut down so much at backstroke (which is so awkward with Yorkshire Tails).

At that time Yorkshire tails were obviously seen as a good solution to a problem (sore hands with extended ringing). Furthermore they were clearly a great success, as they spread to countless Yorkshire towers. The original design must have been readily accepted as, I can assure you, thrifty Yorkshire ringers would not have dug into their pockets for these more expensive ropes if no benefit was seen!

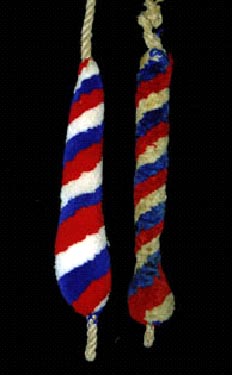

A comparison of the handling

difficulties with a

2001 Yorkshire Tail compared

with an illustration from 1879

"In Yorkshire, the ropes, instead of being doubled back at the end, as in the South, are made.with a single length below the sally, the last fifteen inches or so of which has also tufting woven in."

Have you rung at a tower with Yorkshire tails recently? If not you might have to get in there quickly as the number of sites is dwindling! Many ringers I meet outside Yorkshire have the impression that Yorkshire ropes are still widespread in the county. Even fellow Tykes are largely unaware that there are now only six towers left with full sets and three with part sets! Undoubtedly these tail ends were once ubiquitous in Yorkshire (and also in parts of Lancashire too) so what has lead to this (terminal?) decline? Yorkshire tails towers have to put up with the most vehement criticism from neighbouring ringers! Anti-Yorkshire tail passions are raised which would do justice to a debate on nuclear disarmament or water fluoridation! Thus an even more intriguing question arises: if Yorkshire tails are now so despised how was it that they originally became so popular?

2001 version with a 1970s tail

I learnt to ring (on Yorkshire tails) at the age of 11 and had no difficulty grasping both sally and tail in my eager little hands. As new ropes were delivered during the 1970s we smiled at how fat and cumbersome they were and promised ourselves that they would soon 'bed in'. During the 1980s, I found myself (quite by chance) a member of another Yorkshire ropes tower. The problem of fat tail ends seemed to worsen with every batch of new ropes we ordered. The tight well-defined 'bulb' at the bottom which prevents the hand slipping off, was developing into an enormous pear-shaped handful. Combined with the tendency I see at many towers now, for the thickness of sallies to have crept up from 1½" diameter to almost 2", young learners were finding it impossible to manage the thickness of both tufts together and we could see that handling faults would be the result. After 10 years use when, the plain part of the ropes were worn out, these tails were perhaps just reducing to a manageable thickness! Even worse, the new Yorkshire tails were increasing in length (and thus weight) and some were produced with rope stubs of up to 6" below the tail end which were capable of producing eye injury. It was obvious that we had all 'lost the plot'. There have always been critics of Yorkshire tails but now we were giving them real ammunition in their quest to convert us all to plain ropes. One by one towers have fallen by the wayside and although the end is not yet quite in sight it could be just over the horizon. Who does one turn to in such circumstances? Who is the keeper of the secret of making perfect Yorkshire tails?

The Ringers?

Because most towers have a steady turnover of ringers and most ropes last about 10 years before replacement there are not many people at Yorkshire rope towers who's memories cover many previous sets. Even where this is the case it's easy to be persuaded that the rope maker knows best and perhaps tails were always too bulky when new.

The Ropemakers?

In this age of mass production it's easy to forget that the production of church bell ropes is still a craftsman's job. Furthermore, all our ropes are made by just a handful of these highly skilled but very individual people. They too have a turnover of staff as the years go by. There's no guarantee that your new set of ropes will be made by the same person, to the same design you had 10 years before. There's no 'industry standard' agreed between the firms. Why should ropemakers understand the features they design into their Yorkshire tails? How many rope makers are ringers in Yorkshire tails towers! (None, I would venture) It's wrong to assume that the man making the tail has the slightest understanding of the subtleties of handling it when ringing. Also, bearing in mind the number of Yorkshire tails towers and the life span of a rope I calculate the average ropemaker could wait 5-10 years between orders for Yorkshire tails! A situation hardly conducive to the production of a consistent product.

It seemed to me that it was time to find out what Yorkshire ropes had been like in the 'Good Old Days' when the idea really caught on and to ask modern day ringers for a list of what they dislike about our current tails. For that reason, in 1998, a survey was sent to all the Yorkshire tails towers. There was, predictably, a majority opinion that they had become too fat, too long and likely to have an 'eye-remover' stub of rope at the end. During 2002 I made an effort to visit the practice night of all the Yorkshire tails towers and get as much feedback as possible.

Even more interesting were the discoveries of a few, ancient (but un-dateable) Yorkshire tails of such sylph-like construction as to make our current ropes appear positively obese. Here were tangible examples of how the design had drifted away from the original concept. It's remarkable how these old tails escape being discarded! Some languished in the darkest recesses of the steeple keeper's rope box, some are retained as blackboard dusters but undoubtedly the best hunting ground is the chiming rope, long forgotten by the ringers, but still often to be found at the base of the tower.

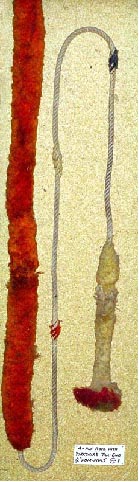

Bingley's Pom-Pom

rope

There are several remarkable features of this venerable 4-ply rope: apart from its delightfully slim Yorkshire tail of pure white; the bobble at the end is coloured red/white/blue/orange! Between sally and tail there are three pom-poms, one red, one white and one blue. When examined by a ropemaker it was found that some of the material might be silk or at least very fine worsted. The very end is so skilfully worked that no terminal 'stub' can be felt at all. It is possible that this tuft was worked into the rope by hand after manufacture.

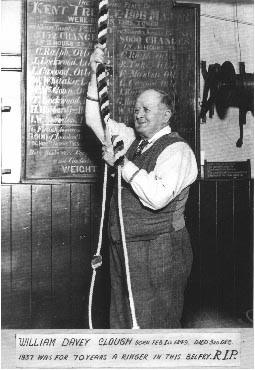

The only known photograph of a

Pom-Pom rope in use.

Courtesy of Otley ringers.

All of the old ropes discovered had much shorter, thinner Yorkshire tails than those of today. They are similar in fact to the demands of present day ringers. The original concept may not have been another length of sally but merely the thinnest padding of the rope required for comfort.

Even I can see the drawbacks of badly made or adjusted Yorkshire tails and wouldn't shed many tears if they were gone for good. However I think it would be rather sad if Yorkshire tails were to disappear, judged only on the overweight examples of recent years. Armed with my research, I feel it my duty to offer to the Exercise (probably for the first time) one possible standard design for the Yorkshire tail.

Perhaps now we like can stop running around like headless chickens and tell our bewildered ropemakers exactly what we want! So it is that I present the 'Slimline Standard' for Yorkshire tails. The features are: a thickness of 1 3/8"; a length of just 14"; a very sharply defined spherical 'bulb' at the bottom (2 1/4" diameter is sufficient to prevent the hand slipping off) and similarly a sharply defined shoulder (if required, one hand can grip effectively above this during dodging); all this to work with a sally of just 1 1/2" to 1 3/8" diameter. Click here for a pdf version of the 'Slimline Standard' to print and give to your ropemaker.

I would very much like to acknowledge the generous help I have had from ringers and ropemakers alike during this project and to express my grateful thanks for their tolerance of my endless questions about such a trivial subject! Especial thanks to Christopher Groome, The Ringing World and Iain Anderson for permission to publish material to the web site.

Now I don't expect all ringers will like this design but perhaps having visited us and tried the first 'Slimline Standard' rope recently manufactured and fitted to one of Bingley's bells, perhaps some of the critics of fat Yorkshire tails might find they can agree with these final words from Jasper Snowdon:

"these ends are much softer to the hands, and very much lighter and less clumsy than those with the double (i.e. plain)-ends."